BULLETPROOF GLASS

GuS: Decades of experience in manufacturing composite and bullet-resistant glass

Since the foundation of our company, we have worked on producing flat bullet-resistant glass for civilian as well as military purposes.

For more than 15 years we have been experts in manufacturing laminated safety glass (LSG) using composite technology, which includes diverse materials such as polycarbonate and transparent ceramics.

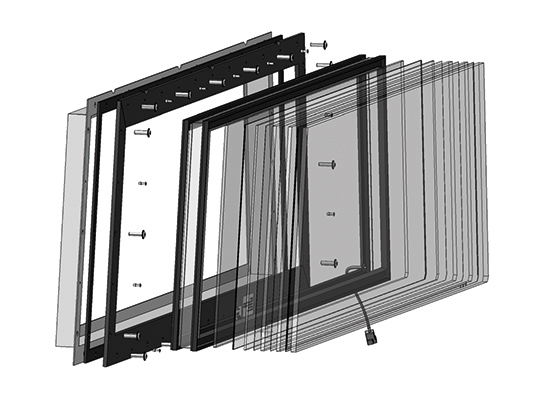

Laminated Safety Glass Technology

- provides a weight reduction of 10 to 20 percent at the same ballistic protection level, which enhances the vehicle’s features (e. g. wider range, additional load and better driving performance.

- allows the manufacturing of significantly thinner glasses, which ensure better optics and material savings

- prevents splinters from entering the vehicle during an attack

After implementation of the LSG technology, we were also able to increase the durability of the bulletproof windows thanks to our continuous development in bonding technologies. Additionally, we refine the edges of the glasses to increase their quality and guarantee improved optics and a more accurate fitting for the assembly.

We use different types of glass to create transparent armor that have been tested ballistically as well as environmentally according to MIL or TL and have also been tested and approved by the German Federal Armed Forces. Additionally, our bullet-resistant glasses have been approved by the German Federal Bureau of Motor Vehicles and Drivers in accordance with German traffic regulations (StVZO).

Since 1995, GuS' bulletproof glass windows have been certified for the German Federal Armed Forces and used in army vehicles deployed internationally.

In order to guarantee the highest level of safety, we develop vehicle-specific solutions with our customers and already take the relevant requirements into consideration during the first construction phase. For example, we employ force-field analyses and simulations.

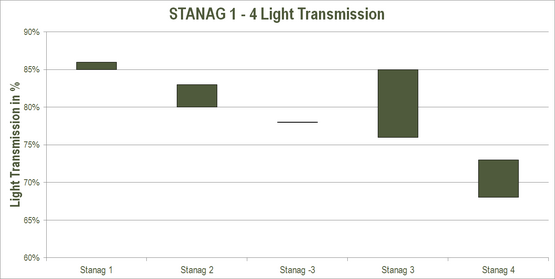

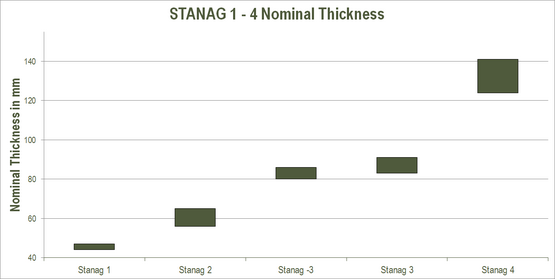

For different requirements and threat scenarios, we offer you composites in accordance with STANAG 4569 (levels 1 to 4), BR classes of DIN EN 1063 or NIJ (0108.01) respectively.

All bullet-resistant windows additionally provide:

- Protection against mine explosions, IEDs and EFPs

- CBRN defense

- Fuel resistance

- Compatibility with diverse night vision devices

The windows can also be upgraded with:

- Interference laser protection

- EMC shielding

- Increased UV protection to protect man and material

- Increased stone-chip and scratch resistance

- Transparent window heating for dissolving condensation and de-icing

- Anti-reflective coating

- Tints

Display projection for efficient information transfer

The driver should always have everything important in his sights. Unfortunately, many displays require the eyes to constantly be in motion. With the innovative display projection inside the bullet-resistant glass windows, this is no longer necessary. A fluorescent information system shows important information in the armored glass windows and can thus reduce communication and reaction time drastically while supporting the handling capability of the vehicle.

The displays can be selected freely and include, for example:

- Navigation device

- Rear-view camera

- Passenger or vehicle-group communication

- Instrument display

- The vehicle’s technical data

- Warnings

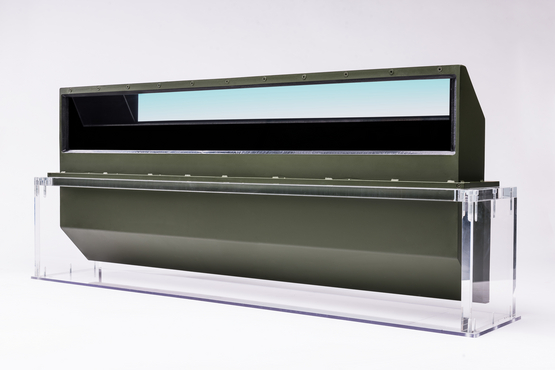

Panoramic periscopes as an alternative to armored glass windows

With a width up to 1 meter a panoramic periscope can replace a STANAG level 4 glass, while offering more protection and at approximately 90 per cent less weight than a conventional screen. It’s manufactured with GuS’ latest generation in adhesive technology. The periscope is designed for the driver and the commander to see through one object. You need more information? Try our flyer which you can get here.

Inexpensive and reliable:

Repair instead of replacing

During any military operation, damage can occur, for example from rock strike or scratching of the polycarbonate layer on the inside of the windows. Professional diagnosis clarifies whether a scratch is actually dangerous for the passengers. Based on this, it is decided whether repairs need to be made and if so, what repairs are necessary to make the window completely functional and safe again.

ADVANTAGES OF THE RESTORATION BY US

- Cost- effective and time saving solutions

- 100% restoration of old bullet- resistant glasses

- Less downtime of the armored vehicles

- Certified repair methods

We guarantee the same quality for repaired glasses as for OEM Products.