Research and development for cutting-edge customer-oriented and operational innovations

Our research and development department (R&D) is one important central element of our company.

1. Research

Our R&D department’s main tasks result from emerging customer requirements, experience gained over years, and the latest innovative technologies and research results.

- In addition to our own research, we rely on knowledge gained from our network of universities, technical universities, Fraunhofer Institutes and other research institutes. In particular, this includes the studies of general and physical chemistry as well as materials science.

- For example, one of the core research areas is innovative adhesive technologies.

- Beyond this, we test cutting-edge materials, such as sapphire glass and transparent ceramics, in order to increase the durability of our products.

- Our regular patent applications point out our innovative strength.

2. Development

For us, product development means to meet customer requirements, i.e. developing the best overall vision concept for a vehicle or optimally implementing specifications.

Our customer-oriented project management and teamwork allow you to rely on prompt support and the quick and dependable implementation of projects.

By providing a contact person for all phases of the project – from designing to prototype development to pre-series and series production – and with constant technical support, we ensure the success of your project.

Furthermore, integrated product support takes place in the design phase where we create technical drawings with the most current version of the 3D CAD system, CATIA. Compatible with all current 3D CAD systems it allows us to seamlessly exchange data with our customers and suppliers.

3. Material testing and stress tests

Material testing and stress tests for optimized products and guaranteed quality

The most important aspect our products must guarantee is the safety of the passengers in the vehicle. Our quality insurance sets a high value on this.

- Small arms and FSP fire testing are the most important factors for evaluating the periscopes and armored glass. The ballistic tests can be performed in various conditions to test the glass composite’s bullet resistance. GuS products are tested and approved by the German Armed Forces and the BAAINBw.

- We also perform comprehensive environmental tests and, for this purpose, have our own in-house testing lab that allows us to assess the limits of materials and products and thus continually improve durability and functionality.

- We simulate the stresses that act upon glass panes and periscopes. Stress examinations that analyze the connections between glass composite and frame can also be performed.

- We perform optical tests to determine whether functionality of our composites and adhesive technologies remains completely intact or material defects occur.

- Finally, after computer-aided simulations (CAS), we test the results in situations that are as close to real life as possible, e.g. bombardment attempts, environmental tests, etc., before offering our new products to our customers.

4. Recent developments and outlook

Recent developments and outlook

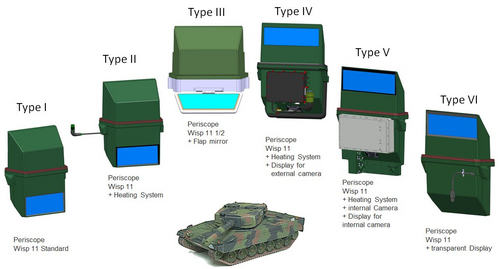

As the leading producer of periscopes, we have been able to continuously increase the added value of the periscopes through, for example, adding heating systems, space-saving flip mirrors or by combining them with displays and cameras.

With regard to safety glass, manufacturing innovations that reduce weight in proportion to protection are of special interest. In this area, we have taken a leading role as the producer of glass composites with our panorama periscope, which is a new generation of utmost protection and weight savings: 90% of weight saved – while retaining 100% ballistic protection.

After having established itself in the military sector for many years now, GuS is focusing more and more on requests for civilian uses. Our composite safety glasses can also be used for protective panes in industrial production facilities or in unusual architecture projects, for example as glass floors, stairs, banisters, etc.

Please approach us with your project: Our competence lies in the individual design of safety products made of glass composites.